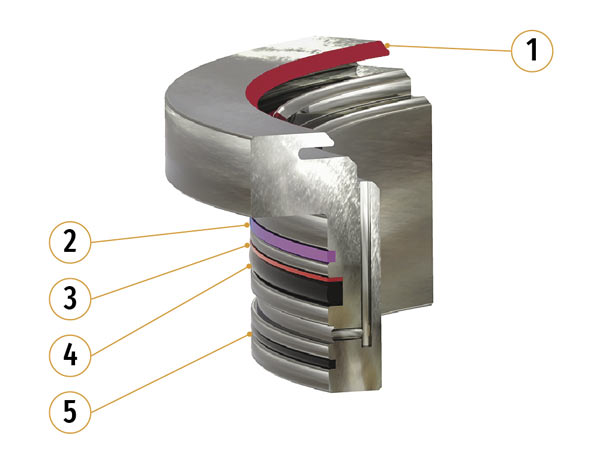

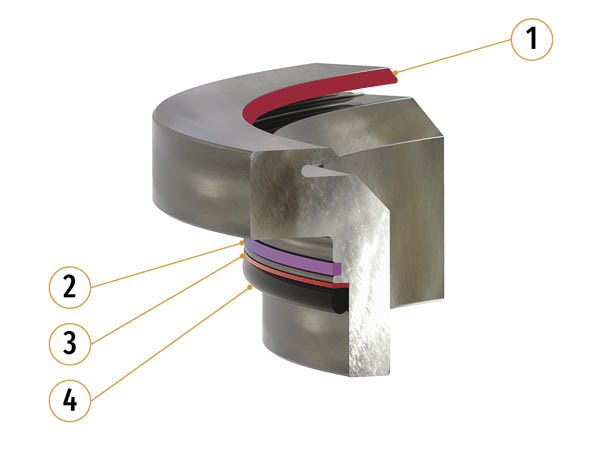

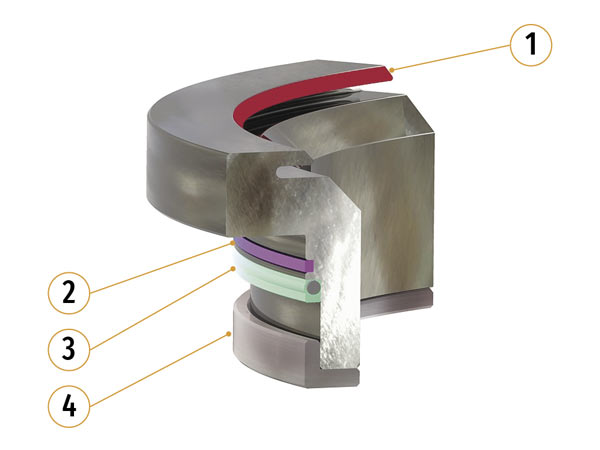

These materials come in the form of powders that are sprayed at high speed on the sealing profile of the seat by means of a particular technological process and then proceed to grinding until the thickness specified by the project.

The coatings above mentioned are ideal for valves subject to the passage of corrosive or impure liquids and high pressures and high operating temperatures.